Introduction

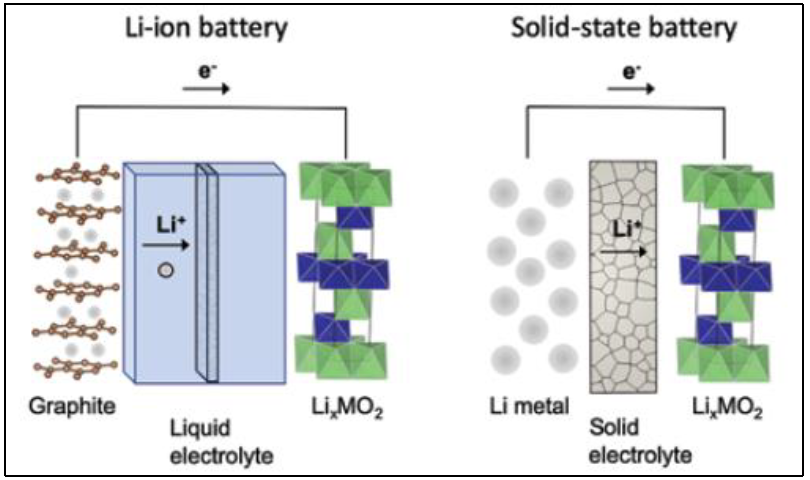

Solid-state lithium-ion batteries use a solid-state material as the electrolyte portion of the battery replacing the traditional liquid electrolyte. All solid-state lithium-ion batteries are defined by a solid-state electrolyte and its anode material, which is a solid lithium metal. Moreover, the working principle of solid-state lithium-ion batteries is the same as that of liquid batteries.

The technical development of solid-state lithium-ion batteries adopts a gradual conversion strategy according to the contained electrolyte mass percentage, the liquid electrolyte content gradually decreasing to the final product all-solid-state battery. Solid-state lithium-ion batteries include semi-solid batteries, quasi-solid batteries and all-solid batteries.

Lithium-ion Battery Category Types

Semi-solid batteries are the stage of transition from liquid lithium batteries to all-solid-state batteries. The mass production of semi-solid batteries can provide a buffer stage and lay the foundation for the early layout of the all-solid-state battery industry chain. Specifically, lithium-ion batteries can be divided into the following five categories:

- Liquid lithium battery: During the manufacturing process, the batteries only contain liquid electrolytes and do not contain solid electrolytes, including liquid lithium-ion batteries and liquid metal lithium batteries.

- Gel electrolyte lithium battery: Belongs to the category of liquid lithium-ion batteries. The liquid electrolyte in the battery exists in the form of gel electrolyte and does not contain solid electrolyte.

- Semi-solid battery: Both solid electrolyte and liquid electrolyte exist in the cell, the mass or volume ratio of the liquid electrolyte is relatively large, and the electrolyte content accounts for 5%-10%.

- Quasi-solid-state battery: The quantity of the solid electrolyte in the battery is higher or the volume is larger in the battery, and the electrolyte content accounts for 0%-5%.

- Hybrid solid-liquid lithium battery: There are both liquid and solid electrolytes in the cell. The aforementioned semi-solid and quasi-solid batteries are all types of hybrid solid-liquid lithium batteries.

- All solid-state battery: The battery core is composed of solid electrodes and solid electrolyte materials. Within the working temperature range, the battery cell does not contain any mass and volume fraction of liquid electrolyte.

Solid-State Battery Component Materials

The main components of the solid-state lithium-ion battery cell are the anode and cathode active materials and the solid electrolytes:

- Anode: Anode active materials are lithium metal and silicon. Lithium metal enables the highest possible energy density, but the technology for processing them is not yet well-established for largescale manufacturing. The energy densities of silicon materials being achieved are lower than that for lithium metal anode.

- Cathode: Active materials are transition metal-based oxides (NMC, NCA) and lithium iron phosphate (LFP). These materials are used in liquid lithium-ion batteries and supply chains, and processing routes are already established. Currently, the highest energy densities can be achieved by using NMC/NCA layered oxides.

- Solid electrolytes: The three groups of solid electrolyte materials are oxides, sulfides and polymers. The oxide solid electrolyte group consists of materials all containing lithium and oxygen as the main components as well as various other elements. They generally exhibit high mechanical and chemical stability, but are brittle and have a relatively poor ionic conductivity. The sulfide solid electrolyte group consists of materials all containing lithium and sulfur as the main components as well as other elements. They are mechanically softer and more malleable than oxide materials, but the chemical compatibility to lithium metal and high-potential cathode active material is limited. The polymer solid electrolyte group is dominated by polyethylene oxide, which is in commercial use. However, they have limited ionic conductivities at room temperature, poor chemical compatibility with high-potential cathode active material and a low limiting current density due to the ionic conduction mechanism.

Product Performance Comparison

Compared with traditional liquid batteries, semi-solid batteries have higher energy density. The current material system of liquid lithium batteries is gradually reaching the upper limit. Solid-state electrolyte can match high-energy NCM cathode material. Lithium metal anode, greatly increases the theoretical energy density up to 500Wh/kg from 350Wh/kg for liquid electrolyte lithium-ion batteries. The electrochemical window of all-solid-state batteries can exceed 5V, which is higher than that of liquid lithium batteries (4.2V).

Commercialisation

It will take time for all-solid-state batteries to be put into use, and semi-solid-state batteries are an intermediate solution for the transition from liquid-state batteries to all-solid-state batteries.

All-solid-state batteries advantages include high energy density and good safety performance, but now challenges including the following three aspects:

- Solid-solid interface contact leads to large internal resistance of the battery;

- The ionic conductivity is not high, and the conductivity of the existing solid-state electrolyte is 1-2 orders of magnitude lower than that of the liquid electrolyte; and

- Due to the lack of commercialisation (inorganic solid-state electrolytes and raw materials have not yet been mass-produced to form a supply chain), the cost of all-solid-state electrolytes is higher than that of traditional liquid lithium-ion batteries, and the product yield is low.

Iterative Semi-solid batteries are an intermediate solution for the transition to all-solid batteries.

- Semi-solid batteries retain some amount of electrolyte, and their cycle performance and rate performance are better than all-solid batteries;

- Semi-solid battery electrode materials are soaked in electrolyte, which improves the problem of low conductivity of solid-state batteries; and

- Cost of semi-solid batteries is higher than traditional lithium batteries, but is lower than all-solid-state batteries.

Competitive Landscape

Although Japan, United States, and South Korea were early in the research and development and commercialisation of solid-state lithium-ion batteries, China is taking the lead in realising the mass production of solid-state batteries because it chose the route of solid-liquid hybrid batteries.

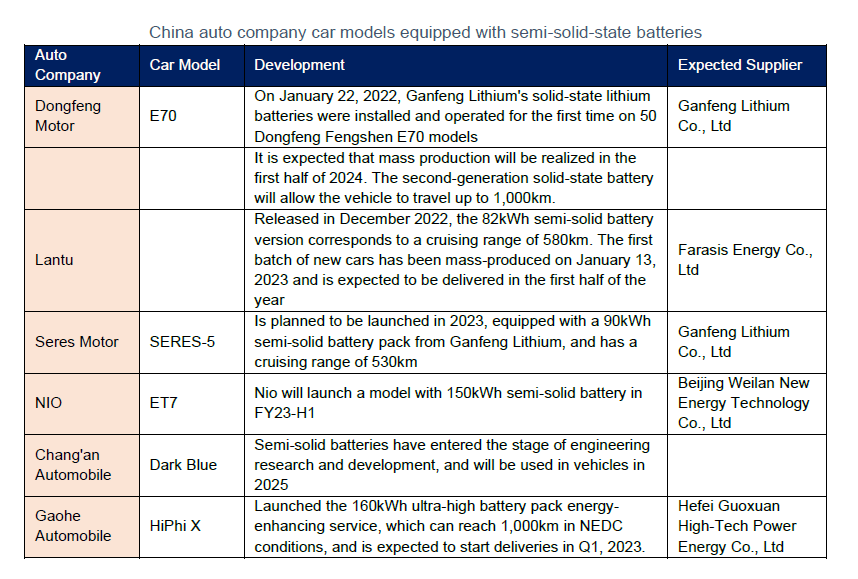

Solid-state battery production lines of Ganfeng Lithium, Qingtao Energy Development and Weilan New Energy have been put into production. From 2022 to 2025, a number of semi-solid battery companies in China will gradually release car-grade batteries for auto companies. For example, Dongfeng will release E70 model, Lantu will release Chasing Wind, and NIO will release ET7 model.

During the iterative process of solid-state batteries, the liquid electrolyte content will drop from 20wt% to 0wt%, the lithium content of the anode material of the battery will gradually increase until it is replaced by metal lithium sheets and battery density is expected to gradually increase to 500Wh/kg.

Purchase the full report today

Click to view the Table of Contents