Introduction

Direct Lithium Extraction (DLE) is a technology that allows for the fast and efficient isolation of lithium from brine, a process that traditionally takes months to years. This technique involves several chemical processes that enable the production of saleable forms of lithium.

DLE has been proven in producing projects in China and South America and is considered a disruptive technology, reducing carbon footprint, operating time, and cash costs compared to traditional lithium extraction and refining methods.

Principal Processing Methods

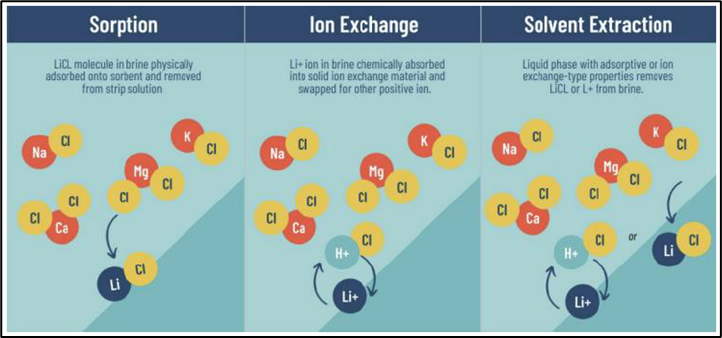

Direct Lithium Extraction (DLE) technologies can be broadly grouped into three main categories: adsorption using porous materials that enable lithium bonding, ion exchange, and solvent extraction. Additionally, DLE innovations are using sorbents, electrochemical, membrane, and ion exchange technologies, each with its own positives and negatives.

Firstly, some specific DLE technologies include the use of resin to adsorb lithium chloride molecules, which is then stripped using water to create a lithium eluate, and further concentrated via reverse osmosis and mechanical evaporation stages. Secondlt, these technologies aim to disrupt traditional practices, reduce carbon, time, and costs, and enable a more sustainable lithium supply, including using geothermal energy as the renewable power source for production.

DLE Technology Advantages and Disadvantages

Moreover, DLE technologies aim to tackle the environmental and techno-economic shortcomings of current lithium extraction methods, with each having its own set of advantages and disadvantages.

Adsorption Method: advantages include it enables lithium bonding and can achieve a high lithium recovery and selectivity, but has the disadvantages of high energy, large amount of fresh water, and produces waste residue.

Ion Exchange Method: advantages include it can achieve a high lithium recovery and selectivity, and some technologies use zero chemicals, however its disadvantage is that it may involve brine pH changes or heating, and requires a large amount of energy and fresh water.

Solvent Extraction Method: advantages include it can achieve high lithium recovery and selectivity, but has the disadvantages of high energy, large amount of fresh water, and produces waste residue.

Commercialisation

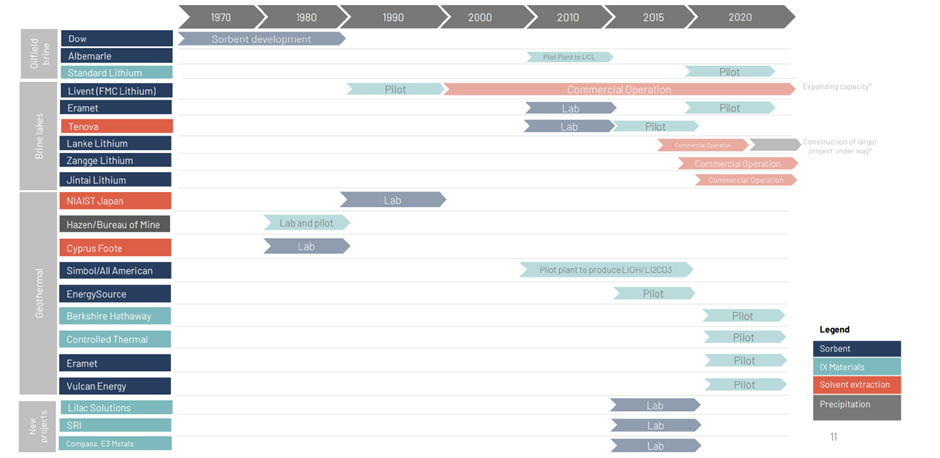

In 1988, Livent took the lead in commercialising direct lithium extraction from salt lakes. Currently, there are many industrial applications and experiments on direct lithium extraction from salt lakes around the world.

Contact us to purchase the full report today

Click to view the Table of Contents

Further reading

Our research reports include an introduction, industry chain, product specifications, processing methods, raw material requirements, cash cost analysis, pricing metrics, future industry development trends, and the competitive landscape. Reach out by email and contact us today to learn more.

You might be interested in our other battery mineral research reports

For Further Information