Introduction

Fluorspar is the commercial name for the mineral fluorite (chemically known as calcium fluoride, CaF2) which, when pure, consists of 51.1% calcium and 48.9% fluorine. In nature, however, small amounts of inclusions and impurities are present.

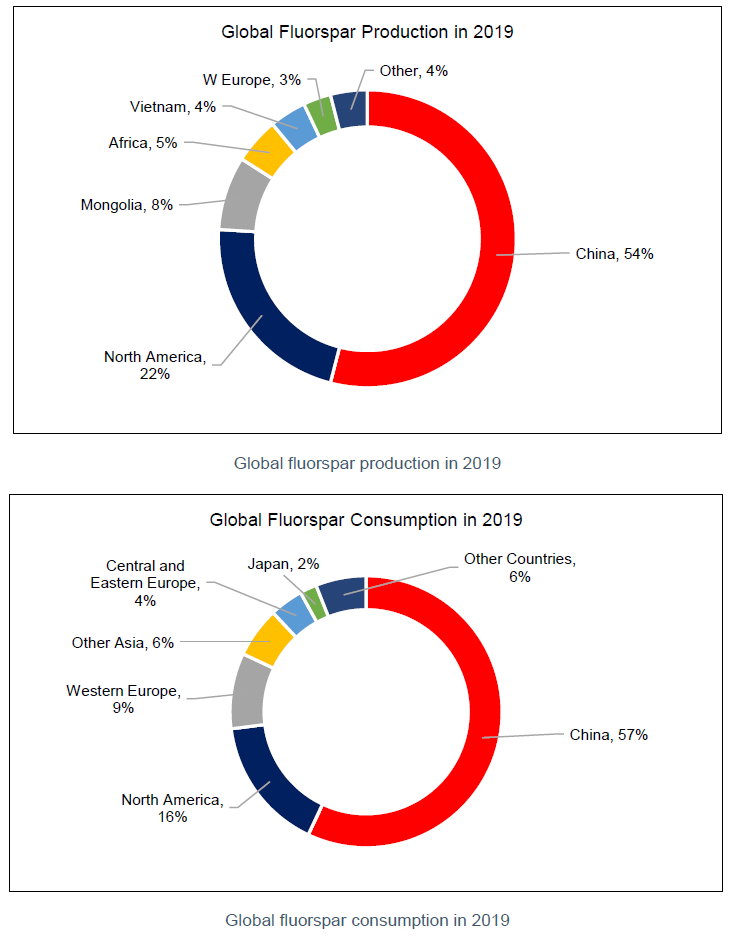

Fluorspar deposits of commercial value have been discovered in more than 40 countries over five continents. Fluorspar mineral resources are unevenly distributed around the world, and are most concentrated in four countries namely Mexico, China, South Africa, and Mongolia. According to the United States Geological Survey, global mineral reserves of fluorspar have increased from 230 million tonnes in 2008 up to 320 million tonnes in 2021.

Principal Processing Methods

The specifications for the three commercial fluorspar market grades are fairly well defined, although countries around the world do have their own standards. In addition, the requirements of individual consumers often vary in detail specifying limits for silica, calcite, ferric oxide, arsenic, lead, zinc, sulphide sulfur, phosphorus, and other impurities or deleterious constituents and particle size. Typical specifications for the fluorspar grades are:

- Acid grade: min.97% CaF2, maximum 1.5% CaCO3, 1.0% SiO2, 0.03-0.1% S, 10-12ppm As, 100-550ppm P and low concentrations of Pb, Cd and Be. Acid grade concentrate is produced by flotation process so its particle size is typically 100 mesh (150μm) or lower.

- Ceramic grade: 85–96% CaF2, maximum 1.0-1.5% CaCO3, 3% SiO2, 0.12% Fe2O3 and trace quantities of lead and zinc.

- Metallurgical grade: 60-85% CaF2, maximum 15% SiO2, 0.3% S, 0.5% Pb. Lump form products come in size ranges with only a small percentage of fines <3mm e.g. 3-10mm/10-70mm.

Commercialisation

More than 87% of global fluorspar production comes from China, Mexico, Mongolia, and South Africa, while the rest of the world produced in aggregate less than 13% of global production.

Contact us to purchase the full report today

Click to view the Table of Contents

Further reading

Our research reports include an introduction, industry chain, product specifications, processing methods, raw material requirements, cash cost analysis, pricing metrics, future industry development trends, and the competitive landscape. Reach out by email and contact us today to learn more.

You might be interested in our other battery mineral research reports

For Further Information