Introduction

Today, NdFeB magnets are ubiquitous products and are commonly found in everyday life, especially in the new economy.

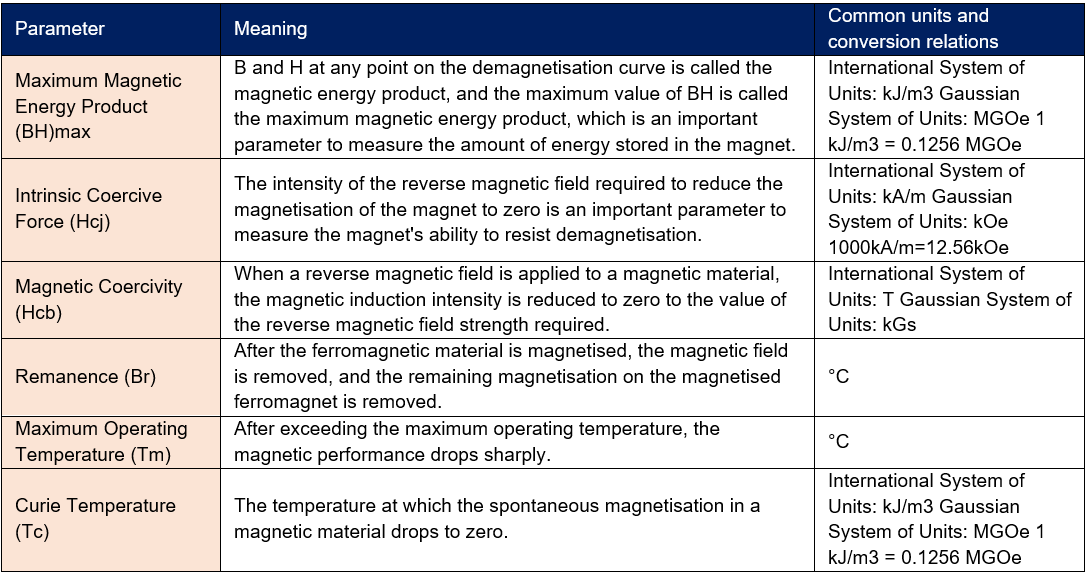

Notably, a magnet is an object that produces a magnetic field, an invisible force that pulls or repels on other magnetic materials. Moreover, permanent magnets refer to an object made from a material that is magnetised and creates its own persistent magnetic field.

Firstly, neodymium Iron Boron magnets (“NdFeB magnets”) are a type of permanent magnet made from alloy material containing the elements neodymium, iron and boron. Moreover, they were developed over 25 years ago and are now the strongest type of magnet commercially available.

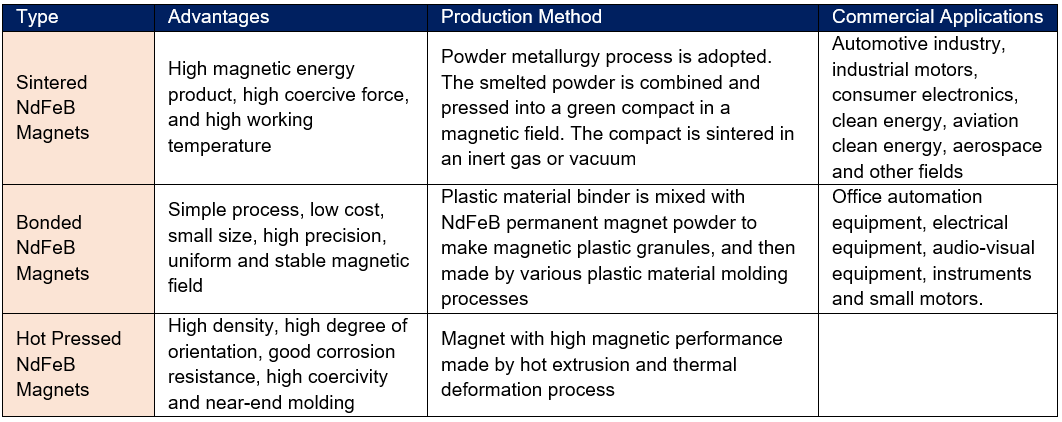

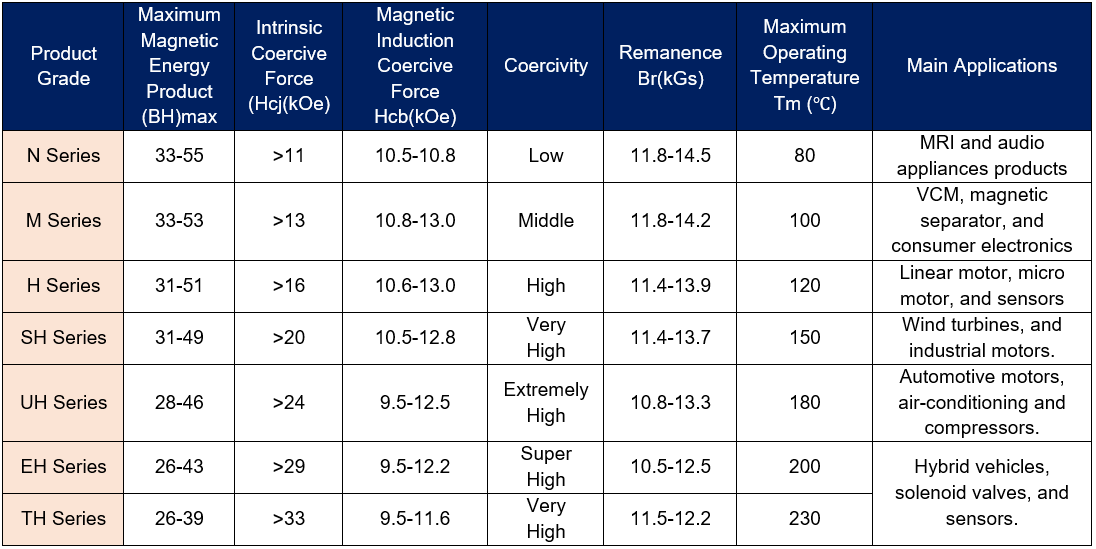

Today, NdFeB magnets are manufactured in a wide range of shapes, sizes and grades and are used in many commercial applications. Moreover, there are three main types defined by production method namely sintering, bonding, and hot pressing. Of which, sintered NdFeB magnets are the most widely used NdFeB magnet material as it currently has the highest magnetic energy yield. Lastly, sintered NdFeB magnets hold a 90% market share in rare earth permanent magnet material production in China.

Most importantly, high-performance NdFeB permanent magnet materials are used in high-tech barrier products found in everyday life such as motors, compressors, sensors, including traditional automotive EPS, new energy vehicle drive motors, wind power generation, frequency conversion appliances, energy-saving motors, and traditional consumer electronics.

Commercialisation

Notably, in 2023, the traditional automotive sector accounted for nearly 40% of global high-performance NdFeB demand, new energy vehicles accounted for nearly 12%. Additionally, other consumer sectors included industrial applications (10.9%), wind power (10%), consumer electronics (9.1%). Lastly, inverter air conditioners and energy-saving appliances accounted for 9% and 8.4%, respectively.

Competitive Landscape

Today, there are currently only five major sintered NdFeB producers outside of China, mainly in Japan, South Korea, and Germany.

- Hitachi Metals Ltd

- TDK Corporation

- Shin-Etsu Chemical Co., Ltd

- Vacuumschmelze

- Star Group Industrial Co., Ltd

Today, new entrants coming to sintered magnet production include MP Materials, USA Rare Earth LLC, Neo Performance Materials and POSCO International.

In addition, within China, high-performance NdFeB magnet material production is mainly concentrated by six listed companies and other private companies:

- Jiangxi Jinli Permanent Magnet Technology Co., Ltd

- Beijing Zhongke San Huan High-Tech Co., Ltd

- Ningbo Yunsheng Co., Ltd

- Yantai Zhenghai Magnetic Material Co. Ltd

- Earth-Panda Advanced Magnetic Material Co., Ltd

- Zhejiang Yingluohua Magnet Co., Ltd

In addition, industry competition is extremely fierce. Importantly, from the global ranking of NdFeB production scale, Chinese enterprises occupy most of the list, of which, high-performance NdFeB permanent magnet materials manufacturers include Zhongke San Huan, Ningbo Yunsheng, Zhenghai Magnetic Materials and other enterprises.

Finally, with reference to the production mode of overseas enterprises, moreover, it is believed a fierce competitive environment, enterprises that focus on specific mid to high end application areas, and focus on R&D, design, and manufacturing capabilities to provide customers with quality services are expected to stand out and become the leader in the market segment.

Contact us to purchase the full report today

Click to view the Table of Contents

Further reading

In addition, our research reports include an introduction, industry chain, product specifications, processing methods, raw material requirements, cash cost analysis, pricing metrics, of which, future industry development trends and the competitive landscape are important. Finally, reach out by email and contact us today to learn more.

You might be interested in our other battery mineral research reports

For Further Information