Introduction

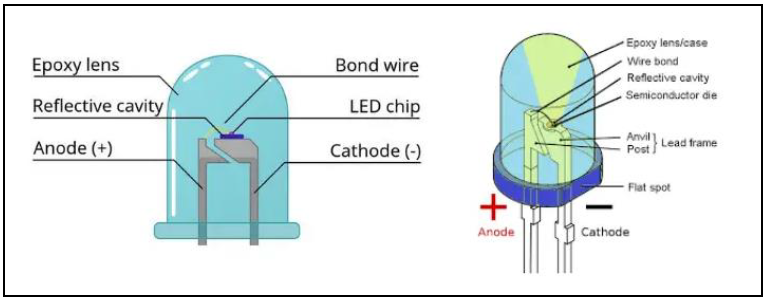

LED are semiconductor chips mounted to a circuit board that use electroluminescence to produce light when current passes through them. LEDs differ from typical lighting methods like traditional incandescent bulbs which generate light by heating a wire filament.

LED lighting offers several advantages over traditional incandescent and fluorescent lighting. This includes energy efficiency, cost savings, environmental benefits, durability, and design versatility. LED specifications include luminous flux, luminous efficacy, colour temperature, colour rendering index, forward voltage, and reverse current leakage. Moreover, numerous factors can affect how well LEDs perform, such as thermal management, drive current, aging, colour shift and optics.

The upstream industry chain consists of:

1) substrate production (mainly from using a sapphire)

2) epitaxy which involves growing a semiconductor material wafer on top of the substrate (using MOCVD technology)

3) dicing into individual chips

4) finally mounting and encapsulation of the LED chip

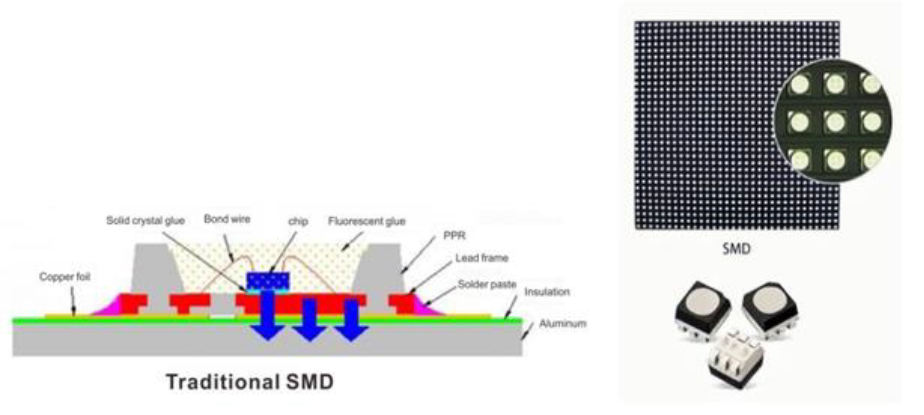

The midstream industry chain consists of the packaging process and packaging equipment, of which the main backlight packaging technologies used are Chip-On-Board (COB) and the main display screen packaging technologies used are COB and Surface-Mounted-Devices (SMD).

The downstream industry chain consists of end users, of which the main commercial applications include but not limited to general lighting, display screens, backlight applications, automotive lighting, signal and indication, and other fields.

LED Manufacturing Process

The LED manufacturing process typically involves design and planning, substrate preparation, epitaxy (growing a semiconductor material layer or ‘wafer’) on top of the substrate, doping, contact formation, dicing, mounting and encapsulation, testing and lighting product.

Commercialisation

In March 2023 soaring raw material costs and high inflation caused by the Russia–Ukraine war and the COVID 19 pandemic in China slashed consumer market demand and increased end product inventories. Therefore, the LED market value shrunk to USD 14.214 billion in 2022 (-19% YoY). Except for the 40% growth rate of the Mini LED backlight market, general lighting, architectural lighting, agricultural lighting, and UV LED sectors all suffered noticeable declines throughout the year. It is estimated that the LED market value will jump to US$21.03 billion by 2027 with a 2022-2027 CAGR of 8%.

Contact us to purchase the full report today

Click to view the Table of Contents

Further reading

Our comprehensive battery mineral research reports include a brief introduction, industry chain, product specifications, processing methods, raw material requirements, cash cost analysis, pricing metrics, future industry development trends, and the competitive landscape. If you have specific reseach topics, reach out by email and contact us today to learn more.

You might be interested in our other battery mineral research reports

For Further Information