Introduction

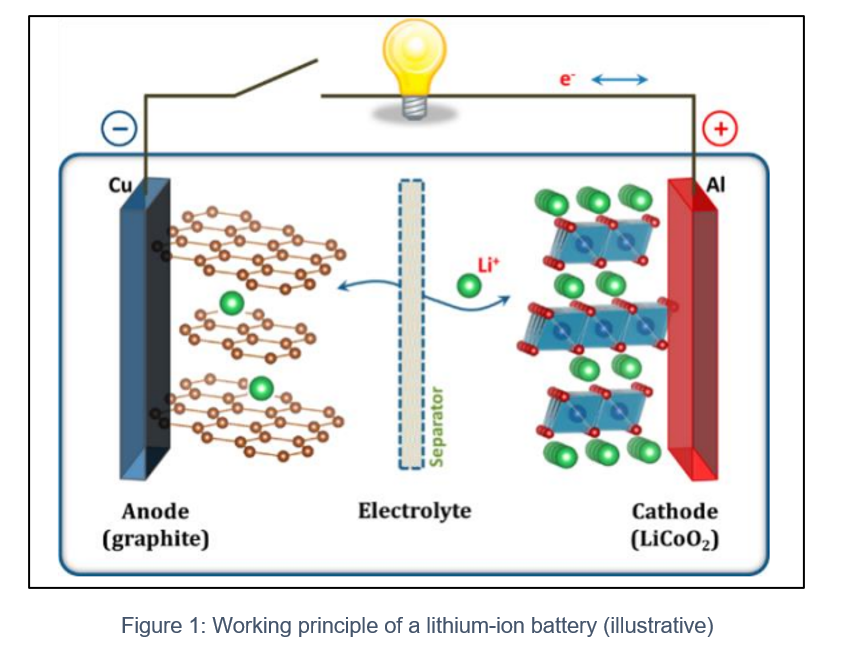

A lithium-ion battery separator is a main component material used in the makeup of high-performance rechargeable lithium-ion batteries. A separator is an insulating film with a large number of meandering and penetrating micropores. Of which the main function of a separator is to isolate the cathode material and anode material. This prevents short circuits within the battery, ensuring free passage of lithium ions to form a charging and discharging circuit.

Separator Product Characteristics

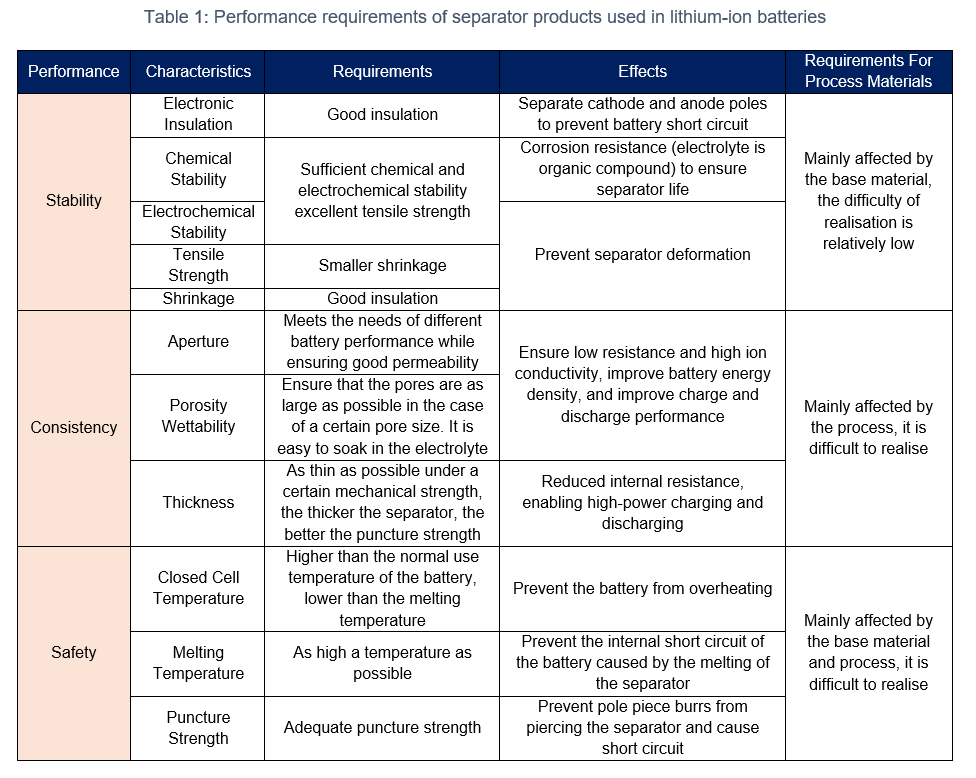

As an important lithium-ion battery component material, the separator plays the role of separating the cathode and anode, effectively preventing the internal short circuit of the battery, while at the same time allowing lithium ions to pass through. For instance, when battery temperature rises, the separator closes to block conduction of lithium ions after reaching a certain temperature. This ensures that the internal circuit of the battery is broken to prevent combustion and explosion caused by excessive temperatures. As it determines the battery energy density and service life, it requires high-performance indicators, which mainly include the following:

- Chemical stability: it should remain stable in the battery and not chemically react with the cathode, anode, and electrolyte. This is mainly measured by corrosion resistance and shrinkage rate.

- Wettability: Excellent wettability can increase the contact between it and the electrolyte. This ensures lower resistance and higher ion conductivity, thereby improving battery energy density, and charge and discharge performance.

- Safety protection: Battery temperature rises during charging and discharging. In extreme cases, a short circuit will release a large amount of heat in a short time. At this time, the physical integrity properties of it ensures that the short circuit is prevented from occurring.

Commercialisation

On the one hand, in recent years, due to the price war in the global industry, the current industry structure is relatively stable and the supply and demand is tightly balanced. Moreover, it is expected that according to current production capacity expansion plans, separator companies will restrict the release of production capacity, keeping the global separator market in a tight balance over the next 2- 3 years.

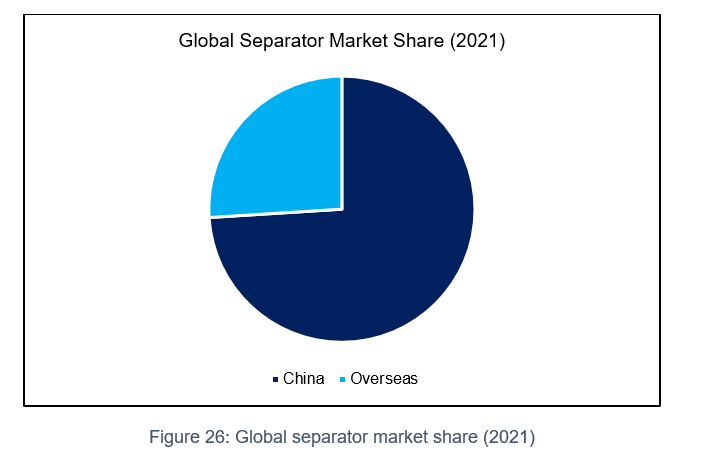

On the other hand, global production capacity continues accelerate and is more and more concentrated by a handful of Chinese companies. Secondly, the China separator industry is dominated by Yunnan Energy New Material Co., Ltd, Shenzhen Senior Technology Material Co., Ltd, and Sinoma Science & Technology Co., Ltd. Moreover, overseas industry is dominated Toray Industries, Asahi Kasei Corporate, UBE Corporation, Wscope, SKI Group, Sumitomo and other companies.

Moreover, from the perspective of global market competition, in 2021, 73.8% of the separator market share was from in China, and the global separator supply will continue to be dominated by China, while the remaining overseas separator market will be dominated by Japanese and Korean companies.

Purchase the full report today

Click to view the Table of Conents

Further reading

Our comprehensive battery mineral research reports include a brief introduction, industry chain, product specifications, processing methods, raw material requirements, cash cost analysis, pricing metrics, future industry development trends, and the competitive landscape. If you have specific reseach topics, reach out by email and contact us today to learn more.

You might be interested in our other battery mineral research reports

For Further Information