Introduction

Lithium-ion battery precision structural parts are an integral part of the internal workings of a lithium-ion battery. Lithium-ion batteries are made up of several internal component materials, namely the cathode, anode, separator, electrolyte, and precision structural parts.

Structural parts consist of aluminium or steel shells, cover plates, connecting pieces, and safety structural parts. Of which, these parts directly affect the sealing and energy density performance of the battery cell.

In terms of cost, taking batteries which use aluminium shells, the outer shell accounts for 16% of the total cost. Therefore, precision structural parts not only play an important role in battery performance but also its share of production cost.

Structural Parts Characteristics

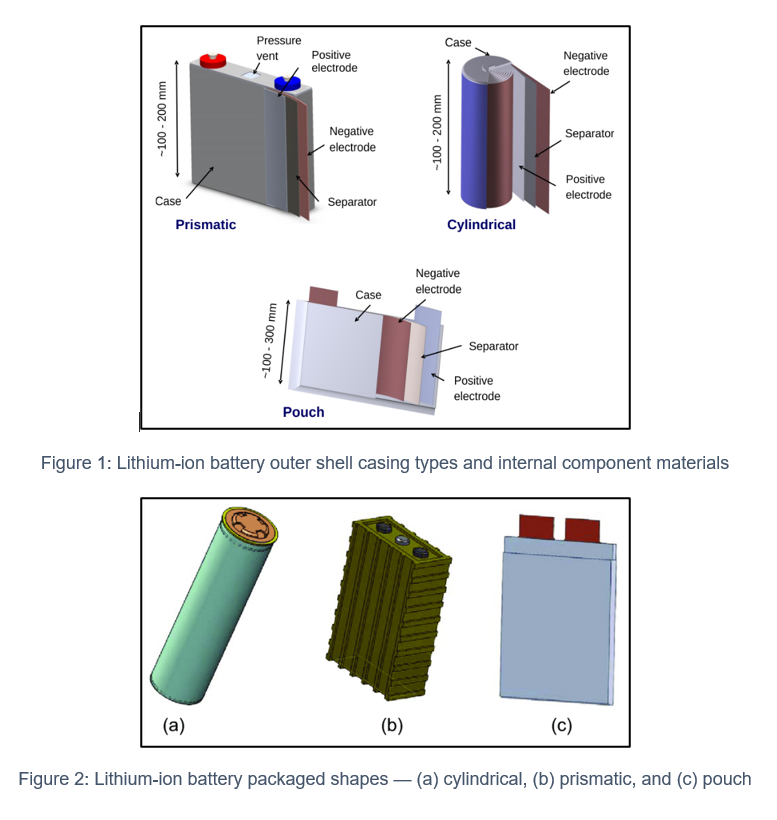

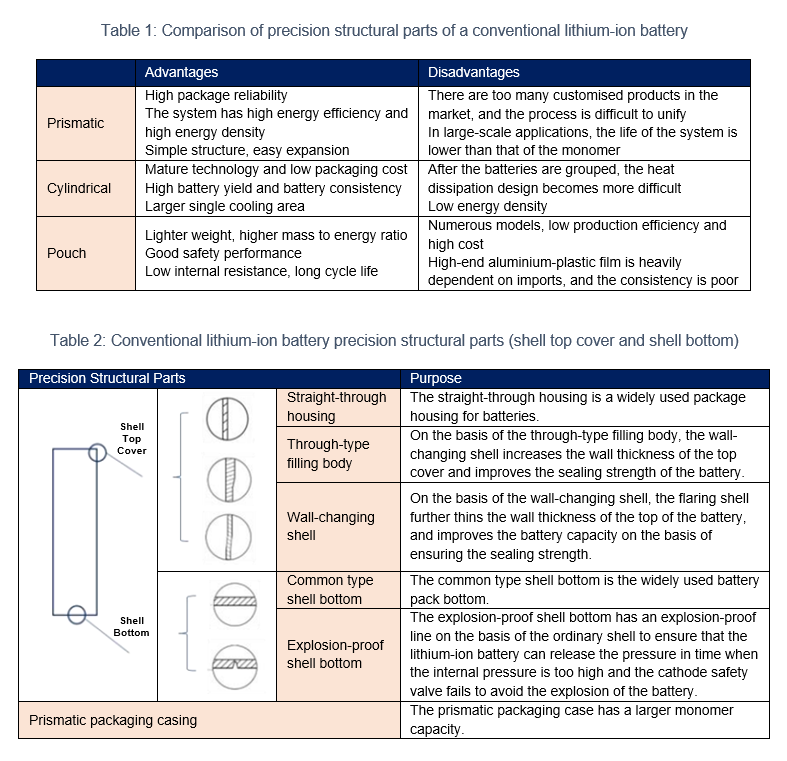

Precision structural parts need to meet performance requirements of lithium-ion batteries being high energy density, high safety and reliability. According to different production processing routes, the packaging shell casing of lithium-ion batteries can be produced in three shapes, namely prismatic, cylindrical, and pouch. Moreover, the structural parts corresponding to these three shapes are namely prismatic structural parts, cylindrical structural parts, and aluminum-plastic film.

As a barrier between the active material in the cell and the entire life cycle of the outside world, the packaging case is an important part used in the makeup of lithium-ion batteries. Packaging shells mainly consist of being either cylindrical and prismatic shells. Notably, the different shell top cover and shell bottom designs of cylindrical shells make battery shells have different performance characteristics, while the advantage of prismatic shells is that they have larger cell capacity.

Principal Production Method

From production to warehousing, battery top covers and casing first go through procurement, then to processing, inspection, and finally warehousing. Moreover, the initial mold development or standardised application is carried out according to customer customisation or industry standardisation. Of which, the production of the top cover requires different processes according to different materials.

Compounding of metal materials requires stamping, cleaning, annealing, and welding, whereas plastic-based materials require production capacity processing and injection molding. Moreover, other component materials of the sealing ring are directly put into the warehouse. Lastly, the shell is made of aluminium, which is inspected and warehoused after stamping, stretching, mouth cutting, and cleaning.

Commercialisation

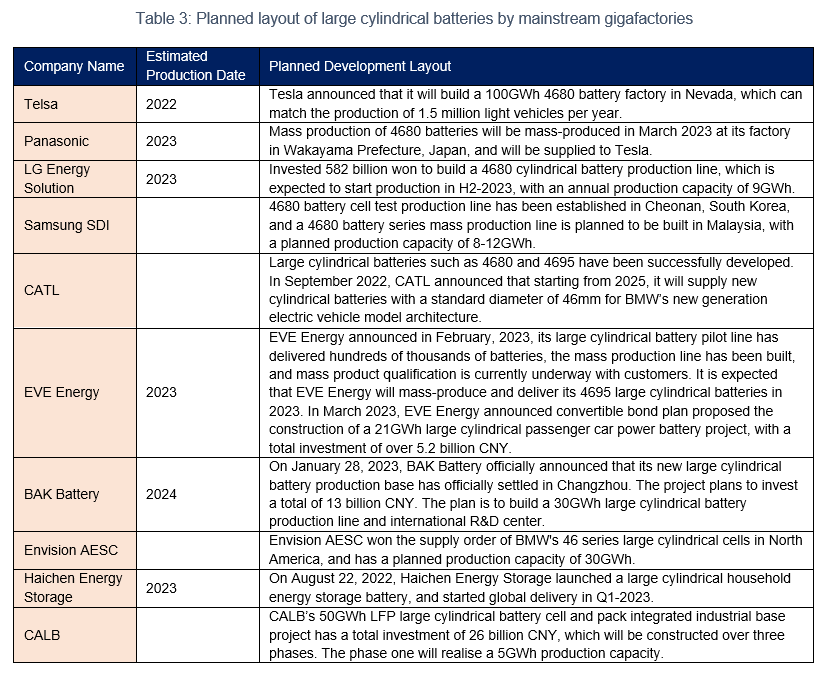

In recent years, many gigafactories have announced their plans to use 4680 large cylindrical batteries, notably BMW announced that it will use 4680 large cylindrical batteries in its new generation electric vehicle models from 2025. Furthermore, according to Tesla, compared to the 2170 battery, the 4680 large cylindrical battery has five times the energy, six times the power output, and a 14% reduction in cost per kWh. As such, the cruising range of an electric vehicle equipped with the 4680 large cylindrical battery can be increased by 16%. Lastly, BMW announced that it will use 4680 large cylindrical batteries in its new generation electric vehicle models from 2025.

Competitive Landscape

In recent years, global demand of EV-Type lithium-ion batteries, energy storage type batteries, and consumer lithium-ion batteries are set increase in the future. As such, by 2026, it is estimated global installed capacity demand for lithium-ion batteries will reach 1929GWh, 996GWh, and 180GWh.

Moreover, based on battery cell consumption, the average unit value of structural parts in 2021 was US$5 million per GWh. As the industry adopts a decrease of 3%-5% per annum, it is assumed that the unit price will also decrease. Therefore, it is estimated that by 2026, the global lithium-ion battery structural parts market size will reach US$1.80 billion. Leading to a growth market CAGR of 39.8% for the period between 2021 to 2026.

Contact us to purchase the full report today

Click to view the Table of Contents

Further reading

Our research reports include an introduction, industry chain, product specifications, processing methods, raw material requirements, cash cost analysis, pricing metrics, future industry development trends, and the competitive landscape. Reach out by email and contact us today to learn more.

You might be interested in our other battery mineral research reports

For Further Information