Introduction

Although lithium-ion batteries have come a long way in more than 20 years of development, their current energy and power density still cannot meet the demands of electric vehicles (“EV”) for cruising range and charging speed. There is an ongoing requirement to develop lithium-ion batteries with excellent energy density and high-rate capability, and LMFP cathode material is becoming a front runner.

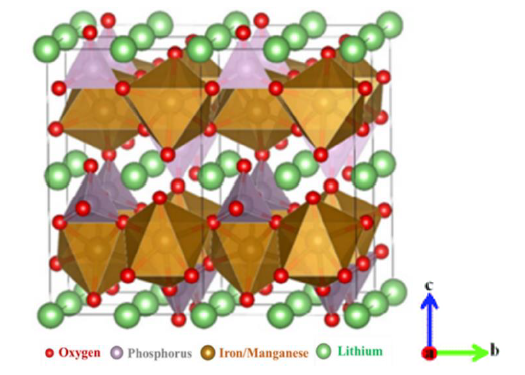

Among various kinds of cathode materials for electric vehicles, the olivine LiFePO4 based material with low cost and high safety is considered to be one of the most competitive materials. Nevertheless, the energy density of LiFePO4 at 90-160 Wh/kg can no longer satisfy the needs, because the working voltage (3.4 V vs. Li/Li+) and theoretical capacity (170 mAh/g) are not satisfactory. Another olivine cathode LiMnPO4 has the same theoretical capacity as LiFePO4, but a higher working voltage of 4.1 V. However, LiMnPO4 has extremely poor conductivity and structural instability during cycling, leading to a low-capacity retention.

Therefore, combining the characteristics of both LiFePO4 and LiMnPO4 by the substitution of Mn2+ at the transition metal Fe2+ site to form LiMnxFe1-xPO4 solid solution has attracted widespread interest and research.

LiMnxFe1-xPO4 combines the high safety and long-life cycle of LiFePO4 and the high energy density of LiMnPO4. Restricting factors for achieving high-rate performance of LMFP include its dual voltage platform, low electronic conductivity and Li+ diffusion coefficient and optimisation of the Fe/Mn ratio.

LMFP Processing Methods

The production process of LMFP cathode material consists of three steps, the ratio of iron to manganese, choice of synthesis route and product modification choice.

Fe/Mn Ratio

In order to improve the energy density and make LMFP have value, the manganese content needs to be ≥50%. Most commercial products produced today are between 64% and 73%, and high manganese is the direction of future research.

Principle Processing Methods

The two methods to produce LMFP cathode material include solid phase methods and liquid phase methods. Of which, solid-phase methods include the high-temperature solid-phase method and the carbothermic reduction method. Whereas liquid-phase methods include the hydrothermal method, sol-gel method and co-precipitation method.

Product Modification Methods

During manufacturing LMFP cathode material, the electrical conductivity can be improved and Jahn-Teller effect can be suppressed by modification methods. The main modification methods are nanometerisation, carbon coating, metal ion doping, compounding with ternary materials.

Commercialisation

- Increasing demand for EVs: LMFP is used lithium-ion batteries for EVs due to its high energy density and load capacity.

- Growing demand for consumer electronics: The increasing demand for consumer electronics, which require lithium-ion batteries with high energy density is also contributing to the growth of LMFP cathode material.

- Investments in battery manufacturing facilities: Increasing investments in gigafactories are expected to boost production of LMFP cathode material.

- Applied to various industries: LMFP cathode material can be applied in various industries such as electronics, automotive, and industrial sectors.

- Technological innovations: Technological innovations in lithium-ion battery technology, including products that cater to high energy density and high load capacity needs are driving the growth of LMFP cathode material.

Competitive Landscape

Firstly, the maximum energy density of an LFP battery is 161.27Wh/kg which has hardly changed over the past four years. Moreover, LMFP with a higher voltage platform and increased energy density is seen as an upgraded version of LFP cathode. Therefore, cathode material and lithium battery manufacturers in China have begun to get involved in LMFP cathode material technology.

Contact us to purchase the full report today

Click to view the Table of Contents

How is the market segmented and which countries are leading its growth?

China is leading production with companies such as Shenzhen Dynanonic, Litai lithium, Tianjin Skoland. Outside of China, there are several companies are involved in the development of LMFP cathode material, including Mitra Chem and other companies.

Is LMFP cathode material becoming more popular than other cathode materials and why?

LMFP cathode material used in lithium-ion batteries advantages include:

1. High safety: LMFP cathode material combines the high safety of LFP cathode material.

2. High energy density: The voltage plateau of LMFP reaches as high as 4.1V, which is higher than LFP (3.4V). This high-voltage platform improves the energy density performance of the lithium-ion battery cell.

3. Low-temperature performance: The capacity retention rate of LMFP cathode material reaches 75% at -20°C, while LFP cathode only reaches 60%-70%.

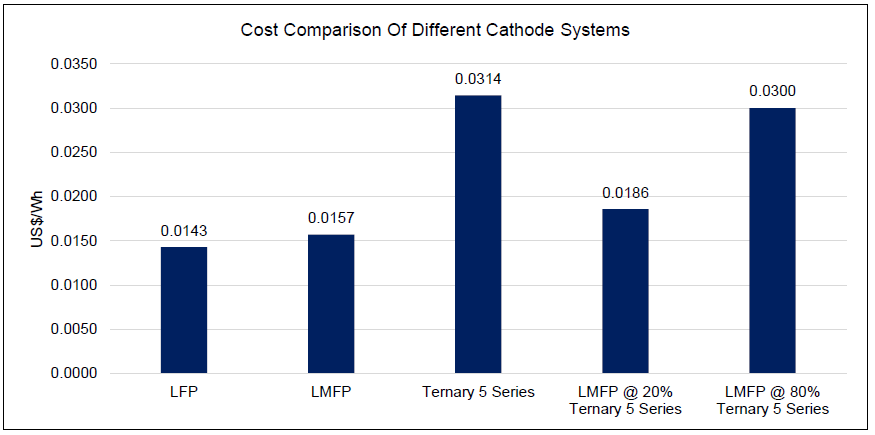

4. Cost advantage: Due to the abundance of manganese, the production cost is only 5%-10% higher than that of LFP cathode.

However, the disadvantages of LMFP cathode material is low electronic conductivity, rate capability and cycle performance.

Whare are the key trends shaping the future of the LMFP cathode industry?

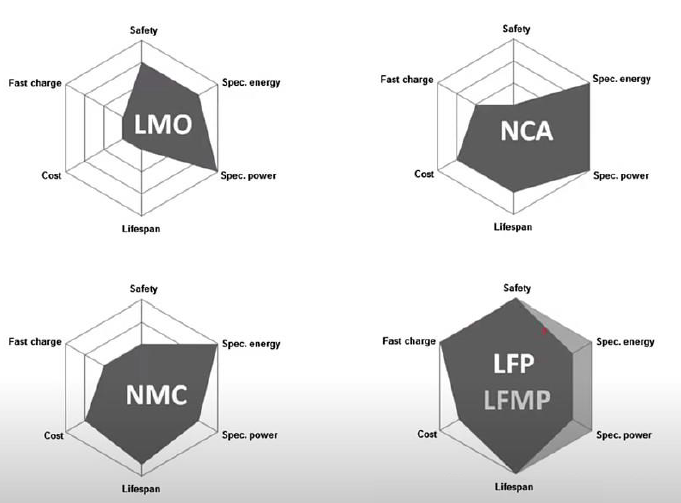

Other cathode materials used in lithium-ion batteries include LCO, LMO, LFP, and NCM/NCA ternary material. Each of these cathode material products have their own advantages and disadvantages in terms of energy density, safety, cost, and environmental impact. LMFP is going to become a niche, low cost, and high performance cathode material in the future.